- Trinamic Motion Control Gmbh & Co Kg Port Devices Driver Download 64-bit

- Trinamic Motion Control Gmbh Instructions

- Trinamic Motion Control Gmbh & Co Kg Port Devices Driver Download Windows 10

- Motion Control Prosthetics

- Trinamic Motion Control Gmbh Inc

Trinamic Motion Control Gmbh & Co Kg Port Devices Driver Download 64-bit

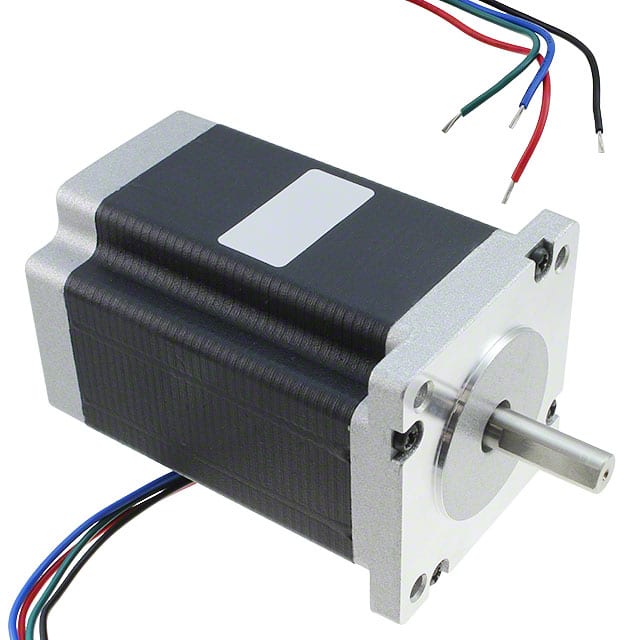

Ranging in size and power, Trinamic has all the motors and drives you need for a perfect fit. Designed for use with industry-leading feature-sets such including specialized voltage and current control, these QMOT drives ensure the best results for your application. For use with closed-loop solutions, these motors are also offered with encoders mounted on the back.

Motion control for lab automation means more than moving actuators from point A to point B with Trinamic. It means reproducible outcomes on every test you run, using the best technologies integrated in proven building blocks. Manufacturers Digi-Key is an authorized distributor of electronic components for more than 1,200 industry-leading suppliers. This means Digi-Key customers can rest assured that the product they order is authentic and comes to Digi-Key directly from the manufacturer.

TRINAMIC MOTION CONTROL. MEV Elektronik Service GmbH Nordel 5a 49176 Hilter a.T.W. Germany Phone: +49 (0) 54 24 / 23 40-0 Fax: +49 (0) 54 24 / 23 40-40. We sell Trinamic Motion Control GmbH all series components, Trinamic Motion Control GmbH Welcome to Integrated-Circuit.com email protected +86-71 +86-11 Account. TRINAMIC Motion Control GmbH & Co. KG Der Sitz der Gesellschaft ist: Waterloohain 5 22769 Hamburg Germany Telefon: +49 - (0)40 - 51 48 06 - 0 Fax: +49 - (0)40 - 51 48.

Popular for their high torque at low speeds and stand still, stepper motors are the drive of choice when precise positioning is needed. Combined with Trinamic's industry-leading technologies turning stepper motor characteristics to your advantage, they transform digital information into perfect physical motion using up to 51,200 microsteps per full revolution.

Flange NEMA | Phase Current | Height | ||||

|---|---|---|---|---|---|---|

| QSH2818-32-07-006 | 11 | 6Ncm | 0.68A | 28mm | 28mm | 32mm |

| QSH2818-51-07-012 | 11 | 12Ncm | 0.68A | 28mm | 28mm | 51mm |

| QSH4218-35-10-027 | 17 | 27Ncm | 1.00A | 42mm | 42mm | 35mm |

| QSH4218-41-10-035 | 17 | 35Ncm | 1.00A | 42mm | 42mm | 41mm |

| QSH4218-47-28-040 | 17 | 40Ncm | 2.80A | 42mm | 42mm | 47mm |

| QSH4218-51-10-049 | 17 | 49Ncm | 1.00A | 42mm | 42mm | 51mm |

| QSH5718-41-28-055 | 23 | 55Ncm | 2.80A | 57mm | 57mm | 41mm |

| QSH5718-51-28-101 | 23 | 101Ncm | 2.80A | 57mm | 57mm | 51mm |

| QSH5718-56-28-126 | 23 | 126Ncm | 2.80A | 57mm | 57mm | 56mm |

| QSH5718-76-28-189 | 23 | 189Ncm | 2.80A | 57mm | 57mm | 76mm |

| QSH6018-45-28-110 | 24 | 110Ncm | 2.80A | 60mm | 60mm | 45mm |

| QSH6018-56-28-165 | 24 | 165Ncm | 2.80A | 60mm | 60mm | 56mm |

| QSH6018-65-28-210 | 24 | 210Ncm | 2.80A | 60mm | 60mm | 65mm |

| QSH6018-86-28-310 | 24 | 310Ncm | 2.80A | 60mm | 60mm | 86mm |

| QSH8618-96-55-700 | 34 | 700Ncm | 5.50A | 86mm | 86mm | 96mm |

2-phase stepper motors combined with small optical encoders are perfect for energy-efficient drives with direct feedback. The added encoder supports servo control for increased efficiency, enabling the use of smaller motors. Furthermore, extra monitoring allows for predictive maintenance and robuster designs, ideal for demanding applications.

Flange NEMA | Phase Current | Height | ||||

|---|---|---|---|---|---|---|

| QSH2818-32-07-006-8192-AT | 11 | 6Ncm | 0.68A | 28mm | 28mm | 47mm |

| QSH2818-51-07-012-8192-AT | 11 | 12Ncm | 0.68A | 28mm | 28mm | 66mm |

| QSH4218-35-10-027-10000-AT | 17 | 27Ncm | 1.00A | 42mm | 42mm | 53mm |

| QSH4218-51-10-049-10000-AT | 17 | 49Ncm | 1.00A | 42mm | 42mm | 69mm |

| QSH5718-51-28-101-10000-AT | 23 | 101Ncm | 2.80A | 57mm | 57mm | 73mm |

| QSH5718-76-28-189-10000-AT | 23 | 189Ncm | 2.80A | 57mm | 57mm | 98mm |

| QSH6018-65-28-210-10000-AT | 24 | 210Ncm | 2.80A | 60mm | 60mm | 83mm |

| QSH6018-86-28-310-10000-AT | 24 | 310Ncm | 2.80A | 60mm | 60mm | 104mm |

| QSH6018-86-90-300-10000-AT | 24 | 300Ncm | 9.00A | 60mm | 60mm | 104mm |

Battery-powered devices require a compact solution, including the drive. The GOOT permanent magnet stepper motors offered by Trinamic have a custom motor coil optimized for microstepping at low voltage. With fewer windings of a thicker wire, these small stepper motors deliver excellent performance for improved user experience.

Trinamic Motion Control Gmbh Instructions

Torque | Width | Length | |||

|---|---|---|---|---|---|

| PM20S-020-124 | 0.8Ncm | 0.75A | 31mm | 20mm | 15mm |

| PM25S-048-314 | 0.8Ncm | 1.00A | 38mm | 25mm | 15mm |

| PM35S-048-324F | 2.8Ncm | 0.75A | 45mm | 35mm | 15mm |

| PM42L-048-285D | 4Ncm | 1.00A | 52mm | 42mm | 22mm |

BLDC motors are famous for their durability, efficiency, and controllability. Widely used in many applications, BLDC drives offer relatively high torque with good speed response. Especially when turned into a servo drive with Trinamic's industry-leading ICs and modules, they form robust solutions that last a lifetime.

Trinamic Motion Control Gmbh & Co Kg Port Devices Driver Download Windows 10

Flange | Phase Current | Rated Speed | Height | |||||

|---|---|---|---|---|---|---|---|---|

| QBL4208-100-04-025 | 42mm | 25Ncm | 6.94A | 8 | 4000rpm | 42mm | 42mm | 100mm |

| QBL4208-41-04-006 | 42mm | 6.25Ncm | 1.78A | 8 | 4000rpm | 42mm | 42mm | 41mm |

| QBL4208-61-04-013 | 42mm | 12.5Ncm | 3.48A | 8 | 4000rpm | 42mm | 42mm | 61mm |

| QBL4208-81-04-019 | 42mm | 18.5Ncm | 5.14A | 8 | 4000rpm | 42mm | 42mm | 81mm |

| QBL5704-116-04-042 | 57mm | 42Ncm | 6.68A | 4 | 4000rpm | 57mm | 57mm | 116mm |

| QBL5704-94-04-032 | 57mm | 32Ncm | 5.08A | 4 | 4000rpm | 57mm | 57mm | 94mm |

Incremental encoders are key enablers when working with BLDC motors. They not only increase the application's performance, they also relieve engineers from the increasing pressure of miniaturization and energy-efficiency by allowing for smaller drives. Furthermore, BLDC motors with encoders increase efficiency by reducing down-time to a minimum.

Flange | Phase Current | Rated Speed | Height | |||||

|---|---|---|---|---|---|---|---|---|

| QBL4208-100-04-025-1024-AT | 42mm | 25Ncm | 7.00A | 8 | 4000rpm | 42mm | 42mm | 118mm |

| QBL4208-61-04-013-1024-AT | 42mm | 13Ncm | 3.50A | 8 | 4000rpm | 42mm | 42mm | 79mm |

Monitoring drives not only increases the application's efficiency, it also tells you the state they're in. Enabling to drive the motor with the exact torque and RPM required for an application, optical incremental encoders for brushless DC motors as well as stepper motors make it possible to use smaller drives in applications, allowing for new use cases.

Resolution | Hollow Diameter | a/b/n incremental | |||

|---|---|---|---|---|---|

| TMCS-20-4-8192-AT-01 | 32768 increments | 20mm | 4mm | TTL | yes |

| TMCS-28-5-10000-AT-01 | 40000 increments | 28mm | 5mm | TTL | yes |

| TMCS-28-5-1024-AT-01 | 4096 increments | 28mm | 5mm | TTL | yes |

| TMCS-28-6.35-10000-AT-01 | 40000 increments | 28mm | 6mm | TTL | yes |

| TMCS-28-6.35-1024-AT-01 | 4096 increments | 28mm | 6mm | TTL | yes |

| TMCS-40-6.35-10000-AT-01 | 40000 increments | 40mm | 6mm | TTL | yes |

TRINAMIC is a fabless semiconductor company developing ASSPs for motion control of fractional horse power stepper motors and brushless DC motors. TRINAMIC's integrated circuits are manufactured to the highest standards in the world's most advanced manufacturing plants.

TRINAMIC differentiates its expertise as a combination of understanding the specific requirements of motors and IC design know-how. While the competition often comes from and focuses on semiconductor technology, TRINAMIC is at home in both worlds -- the world of motors and the world of IC design. For customers, Trinamic's application driven approach means that they do not need an in-depth knowledge about motors nor about DSPs or control circuitry in general. Consequently, the design phase is vastly minimized resulting in significant labor and cost savings.

Trinamic´s mechatronics approach – the integration of electronic control, system thinking and precision mechanical engineering – attempts to achieve an optimal balance between the mechanical structure, in this case the motor, and its overall control. For instance, the methodology used in the design of the TMC246 stepper motor driver IC eliminates the need for external components and sensors: The motor is the sensor.

According to the Massachusetts Institute of Technology (MIT), mechatronics is an emerging technology that revolutionizes classical automation technologies. Mechatronic systems in cars will create completely new features such as adaptive light systems to enhance functionality and safety. They will replace pure mechanical systems such as break and steering systems. Applications will surpass vehicles, impacting the commercial and industrial automation environment. As a pioneer in this exciting new area, Trinamic is implementing mechatronics deep into motion control to deliver highly integrated, cost effective solutions with higher functionality and smaller form factor.

Trinamic's motion control solutions are designed for the use in:

With its highly integrated motion control and driver chips, Trinamic is able to offer a complete solution. Download touchstone technoligy usb devices driver. An entire system can be built with an off-the-shelf 8-bit controller connected via an SPI, I²C or parallel interface to Trinamic motion control and driver chips. |

For customers looking for low volume solutions, Trinamic also offers complete modules, including hardware and software for specific motor control requirements. The modules combine Trinamic´s dedicated stepper control and driver ICs with extensive experience in designing custom and off-the-shelf motion control solutions. A powerful, yet easy to use programming environment makes stepper control as simple as a few mouse clicks - cutting six months off the time to market compared to chip-level development.

Motion Control Prosthetics

Trinamic Motion Control Gmbh Inc

The most notable trend affecting the market for fractional horsepower motors is the rising use of DC motors in automotive application areas. Fractional horsepower motors are benefiting from a trend where technological developments and consumer demand are leading to the use of ever-smaller products. According to the latest Frost & Sullivan survey, it is projected that revenues in the market for fractional horsepower motors will be 5.4 billion dollars in 2006.